The oil level should also be checked. Wiring and Bolted Connection Checks for Switchgear and Switchboards.

Transformer Network Protector Protector Networking Transformers

Transformer Network Protector Protector Networking Transformers

Should expect transformer replacement and failures to increase due to this age factor.

How often should transformers be inspected. You should refer to the manufacturers instructions for oil processing practices appropriate for the transformer. DGA or Dissolve Gas Analysis of transformer Oil should be performed annually for 132 KV transformer once in 2 years for the transformer below 132 KV transformer and in 2 years interval for the transformer above 132 KV transformer. Good practice for oil cooled and dry core transformers 500kVA to do a visual inspection eg.

Perhaps every three to six months. Testing of oil in on load tap changers must be performed according to the tap changer suppliers recommendations. If there is a sudden change the transformer should be carefully inspected for leaks and the oil processed if the dielectric is below the 28kV level or water content is above 30 ppm parts per million.

And if you wonder how often you should perform maintenance work on a transformer it is generally indicated once every year. Any abnormal reading suggests that further diagnostic testing or inspection should be done. Wooden poles are typically inspected in cycles of five and 12 years depending on the age of the poles and the utility company.

Testing of oil in transformers should normally be performed 12 months after filling or refilling subsequently annually on large distribution and power transformers. How Often Should PPE Be Inspected for General Industry. Therefore high quality maintenance and accurate diagnostics are important for all.

Posted on February 4 2020 by Complete Electrical Solutions Our heating ventilation and air conditioning systems also known as HVAC are easy to forget about when they are working correctly and impossible to ignore when they are not. You could pick up potential issues overload Checkreset MDIs when fitted oil leaks terminals overheating. Many utility companies use a five-year inspection cycle though some are more frequent and some with low population density and low deteriorationdecay rates are longer than five years.

The nominal period between scheduled tests is one year but this may be longer or shorter depending on the observed accumulation of contamination on the cooling vents. Extreme temperatures decrease the fluids insulation potential. Though not part of OSHAs mandatory guidelines the organization does offer suggestions that include training employees in the importance of conducting inspections on their safety equipment including fall protection devices prior to each use.

Transformer physical inspection. Leakage of oil and reading of MOG Magnetic Oil Gage of tanks. How often installations are inspected is up to the owner of the installation provided such durations do not exceed any regulatory maximums in force.

The criticality of the electrical installation to the continuation of the business often determines how frequently the installation is inspected for example many banks will carry out annual inspections of their installations. 1 Bolted electrical connections should be inspected for high resistance either by use of a low-resistance ohmmeter DLRO calibrated torque-wrench or infrared scanLoose bolted electrical connections can lead to higher energy consumption and eventual equipment failure if not properly addressed. How Often Should I Get My HVAC System Inspected.

Test samples should be taken from the bottom of the tank. Some others must only monitored and fully witnessing are not necessary for these thing the inspection man-days etc. The Action to be taken once in 2 years.

Transformer Maintenance on a Half Yearly Basis Your electrical transformer needs to be checked every 6 months for IFT DDA flash point sludge content acidity water content and dielectric strength along with how resistant it is to transformer oil. It depends under what conditions the transformers have to work. In the future lead times may extend well beyond what they are today.

However from our experience we can assure you that the best thing you can do is have the transformer test results at hand as well as the recommendations from previous maintenances the criticality of the equipment for your business processes the transformer capacity KVA the percentage of use and the transformers current physical condition is to schedule the. Depends to the purchaser decision some prefer stringent monitoring and even assign resident inspector in manufacturing shop and some others relay to quality control system of the manufacture and assign only few days for monitoring points. Current minimum replacement time is around 14 months.

A more realistic time may be 18 months to 2 years. Walkthrough through the switchroom. In case of unsatisfactory oil level in the MOG oil to be filled in transformer and also the transformer tank to be checked for oil leakage.

The fluid inside an oil-filled power transformer must be tested to measure its dielectric strength. One month after initial energization and annually thereafter Gauge readings ambient temperature and kvA load should be measured and recorded. It is generally done with a portable testing unit which applies test voltage that increases in intensity until a breakdown point of the oil is detected.

If routine inspections indicate that cleaning is required periodic tests should be made at the shutdown for the cleaning operation after the transformer is thoroughly cleaned. Maintenance of Current Transformer. If oil leakage is found take required action to plug the leakage.

The oil that provides insulation and cooling properties for a transformer should be tested before the transformer is energized and periodically as a part of a regular maintenance schedule. The calibration of OTI and WTI must be carried once in two years. The following inspections and tests should be performed annually.

Outdoor Electrical Substation Electrical Substation Electricity Fire Systems

Outdoor Electrical Substation Electrical Substation Electricity Fire Systems

Signs That Your Lighting Needs Repairs Cmi Companies Electrical Inspection Electrician Electrical Transformers

Signs That Your Lighting Needs Repairs Cmi Companies Electrical Inspection Electrician Electrical Transformers

Outage Restoration Process Electricity Electrical Substation Transmission Tower

Outage Restoration Process Electricity Electrical Substation Transmission Tower

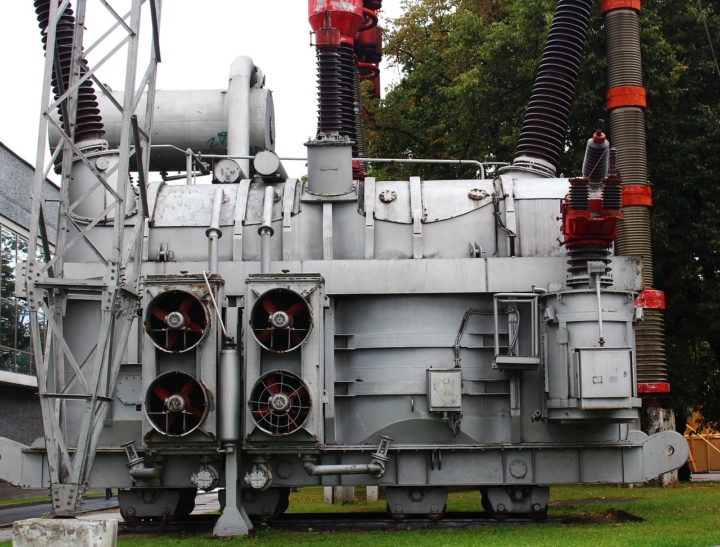

Periodic Transformer Exterior Inspection Visual Reveals Important Condition Information For Example Valves Positioned Inc Transformers Exterior Power Plant

Periodic Transformer Exterior Inspection Visual Reveals Important Condition Information For Example Valves Positioned Inc Transformers Exterior Power Plant

Maintenance Tips For Electrical Transformers

Maintenance Tips For Electrical Transformers

Network Protector Networking Protector Current Transformer

Network Protector Networking Protector Current Transformer

Maintenance Of Transformers A Detailed Checklist Electrical4u

Maintenance Of Transformers A Detailed Checklist Electrical4u

Maintenance Of Transformer Power Transformers Maintenance Diagnostic Monitoring Transformers Preventive Maintenance Maintenance

Maintenance Of Transformer Power Transformers Maintenance Diagnostic Monitoring Transformers Preventive Maintenance Maintenance

3 Phase Transformers Img 2333 700 Jpg 633 731 Electrical Transformers Electricity Electrical Projects

3 Phase Transformers Img 2333 700 Jpg 633 731 Electrical Transformers Electricity Electrical Projects

Because A Transformer Failure Is Usually Of A Very Serious Nature Requiring Extensive Repair And Long Downtime Reg Preventive Maintenance Transformers Repair

Because A Transformer Failure Is Usually Of A Very Serious Nature Requiring Extensive Repair And Long Downtime Reg Preventive Maintenance Transformers Repair

Network Transformer Schematic Networking Transformers Current Transformer

Network Transformer Schematic Networking Transformers Current Transformer

Protection Of A Transformer Directly Connected To A Transmission Line Without Switchgear Transmission Line Electric Power Distribution Transformers

Protection Of A Transformer Directly Connected To A Transmission Line Without Switchgear Transmission Line Electric Power Distribution Transformers

When A Transformer Is Initially Energized There Is A Phenomenon Known As Exciting Current Inrush Inrush Curre Transformers Electricity Electrical Engineering

When A Transformer Is Initially Energized There Is A Phenomenon Known As Exciting Current Inrush Inrush Curre Transformers Electricity Electrical Engineering

Periodic Inspection And Testing Of Power Circuit Breakers Almost Always Includes A Visual Inspection Calibrating The Overcurrent Protec Circuit Breakers Power

Periodic Inspection And Testing Of Power Circuit Breakers Almost Always Includes A Visual Inspection Calibrating The Overcurrent Protec Circuit Breakers Power

Power Transformer Drying Siemens Transformers Siemens Electrical Engineering

Power Transformer Drying Siemens Transformers Siemens Electrical Engineering

99d1124765648 Warning Big Files Mtmte Binaltech Profiles Btstreak2 Jpg 669 1032 Transformers Autobots Transformers Characters Transformers

99d1124765648 Warning Big Files Mtmte Binaltech Profiles Btstreak2 Jpg 669 1032 Transformers Autobots Transformers Characters Transformers

Transformer Surge Arresters Transformers Application The Selection

Transformer Surge Arresters Transformers Application The Selection

Comments

Post a Comment